Do you know how to prevent shipment of goods during shipment?

Do you know how to prevent shipment of goods during shipment? In fact, if you have a good method, it’s easy. And the failure of your pallet to be shipped has been greatly reduced.

When pallets arrive at their destination, a lot of pressure will be borne by them. All these pot holes, restrictions and sudden stops may result in a leak in the tray when the loading occurs. One of the main reasons you don’t want to ignore the damage is probably because of this. There are two things you can do here. If you do this, the failure of pallet cargo during shipment can be maintained.

First, work unitary is loaded correctly.

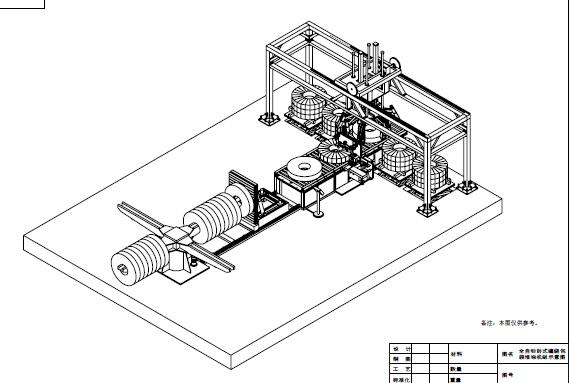

In fact, as we all know, this is your first defense. One of the most popular methods today is stretching the packaging. As we can see, if you pack the load better, you will have less damage to your load. The best thing for you is to use the machine.

However, when you’re effectively packing, it’s a rare thing to know if you want to tell. You can follow these rules because these rules can help you create one of the biggest survival opportunities.

Do you know the number of containers needed for the application? The effect of the pressure stretch film on the load is the containment force. For your load, if it doesn’t have enough containment, then we can see that it has an unnecessary risk of failure. Using a thin film cable to lock the load onto a tray is something you can do. If you’re going to roll the cable and apply it to the membrane underneath the tray, do you know what that does? It prevents the load from slipping off the tray. This is very helpful to protect the product. The cable placement is also very particular, it can make the fork from the Angle of the puncture, as a forklift or a tray, jack picks up the load.