The coiling machien used for the coiling procession in the producing wire rope covered by Pvc for the transportation market. There are company interested in one... Read More

packing

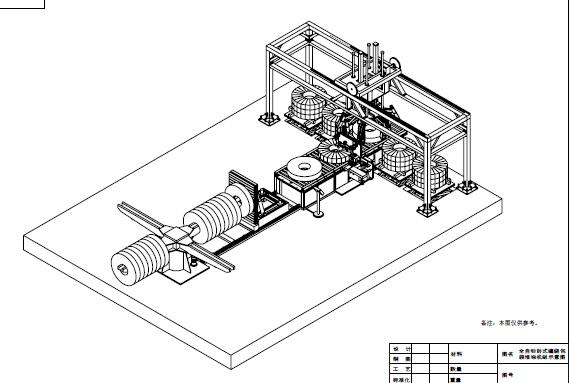

Automatic slit coil packing line Pre-acceptance on August 8, 2019 feedback from FHOPE for the coil packing line 1. Cycle time for packing... Read More

Please let me have the coil information in following list for a roughly price. 1. coil size Coil No. OD (mm) ID(mm) WIDTH(mm) WEIGHT(Kg) 1 2 3... Read More

https://www.fhopepack.com/Customize-orbital-wrapper/Aluminum_wrapping_machine.html We are interested in a horizontal rod and bar wrapping machine. We are looking to wrap steel threaded rod 1-3/4″ diameter up to 3″... Read More

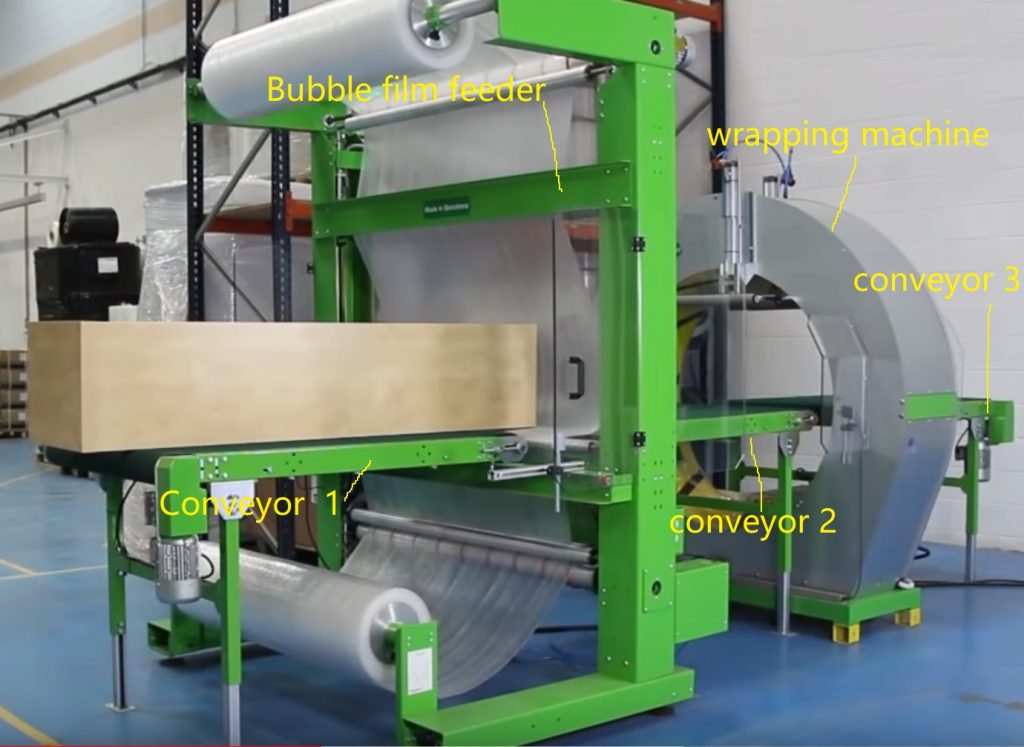

https://www.fhopepack.com/Stretch_wrapping_machine.html We got clients worry about their product. They really think the goods might fall down when it’s on conveyors or the wrapping machine. Here... Read More

https://www.fhopepack.com/Aluminum_wrapping_machine.html https://www.fhopepack.com/Automatic-pipe-bundle-packing-line.html Our PVC pipe bundling and bagging line not just can be used for packing pipes, but also can work on profiles, but there... Read More

https://www.fhopepack.com/videos/horizontal-wrapping-machine-for-glass-door/ We have customers who wants to have a machine for packaging their products-glass door. Seems they have been searching this for a long time,... Read More

Below is an enquiry from an American client, who I have been following for several months looking for a coil wrapping machine for their razor... Read More

PVC pipe pacing line

1 min read

https://www.fhopepack.com/PPR%20PVC-pipe-packing-line.html Hello Tao, I think the machines are interesting, but I’m looking for a machine that can help me to pack drain accessories (PVC .... Read More

Pallet inverter fits your special needs

1 min read

https://www.fhopepack.com/pallet-inverter/ Hi, Good morning to you. Our customer need to purchase a stationary load inverter, basically to change pallets. They handle different container formats (drums... Read More