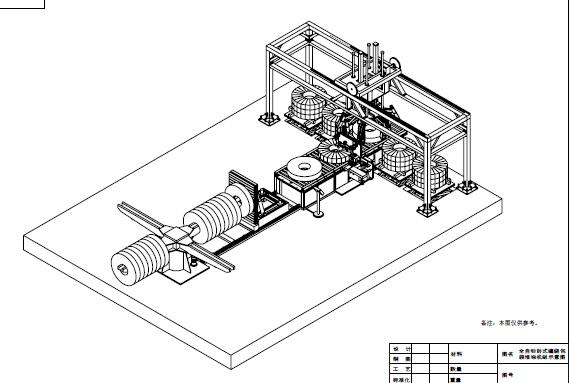

Stretch Wrappers

You can look at an article on mechanical equipment today, which is called, “forklift injuries often happen when people stand too close to a mobile forklift.”

There is no doubt that separating the two traffic flows is the simplest way to mitigate this risk. Add the method of the designated forklift lane, and you can consider that by this method, pedestrians can get an indication that pedestrians are instructed not to walk in. The purpose of this directive is to specify and clearly mark the forklift space for loading, unloading, and pallet packaging, which is also a simple way to reduce pedestrian/forklift traffic. Reducing the number of people working near forklifts is another way to reduce risk. But, as we all know, if you want to achieve this, it can be difficult. However, you can see that the obvious forklift area is a good start.

Do you know what a well-defined loading and unloading zone injury prevention plan is? It’s also a great way to help reduce risk.

Consider semi-automatic or automatic stretch packaging as another way to reduce this risk. Do you know what an automatic stretching wrapper does? In addition to packaging a tray, it can also cut film from the end of the packaging cycle. It can also fix the film on the next load.

Many automated options are also useful, allowing forklift drivers to start stretching the packaging without leaving the forklift.

Risk needs to be reduced.

Putting them on the forklift is the best way to reduce the risk of forklift operators. At the same time, we all know that the best way to do this is to use a stretch wrapper to eliminate the need for manual packaging. If you’re looking at your options now, and you want to know more, it’s ok to check our free guide. It’s also necessary to buy a stretch wrap.