The thing you need to do is avoid stretching and packaging “running around”.

The thing you need to do is avoid stretching and packaging “running around”.

According to the national institute on occupational safety and health (NIOSH), the company reports that many people are injured in forklift accidents every year, and that’s estimated to be 95,000 per year.

This is a risky proposition for those who use semi-automatic stretching packages, whether to open or close a forklift. Do you know when a third of the forklift accident happened? Typically, they occur when the operator installs and disassembles their forklifts, while the operator’s shoulder hurts, concussions, sprained ankles and even fractures.

And we all know there’s a risk. Ergonomics of the manual machine is involved — stretching, stretching, pulling and so on are included. In fact, what we call “running around” means this, all of which adds up to the so-called “running around”.

Completely avoiding these risks is the best way to manage these risks.

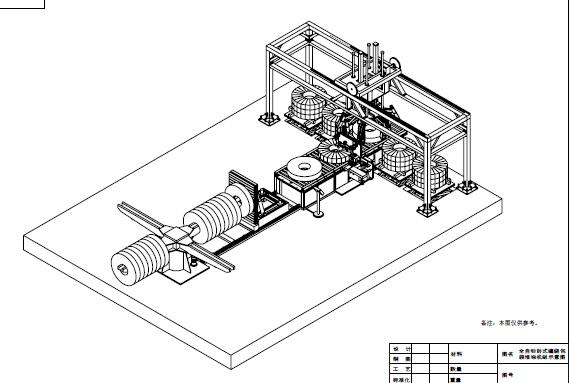

Do you know what the most effective stretch packing in the semi-automatic class does? It can add simple automation – the ability to stretch the packaging is to go to the end of the film and wrap the loop, start wrapping the loop rope switch or remote control device. Activating the forklift is something the operator can do.

Do you know how simple automation works? It not only allows the operator to operate on the forklift, but also the need for physical operation of the stretching package can be eliminated. Security can also be enhanced by it. Plus, two minutes of labor productivity per load is what you see. In the first five years, do you know how much labor costs an average customer can save? It is estimated that labor costs of up to $50,000.

It is obvious that machines, especially cheap ones, do the same thing.