Do you know how to reduce transport loss in the supply chain?

Do you know how to reduce transport loss in the supply chain?

We read a good article, its title as the “reduce packing damage to the supply chain”, – stretch packaging technology is very useful, it can ensure that your pallet load to the right place. Under the right conditions, if you use stretch wrapping technology, you can produce minimal transport damage.

Let’s take a look at some of the key insights of this article, which include:

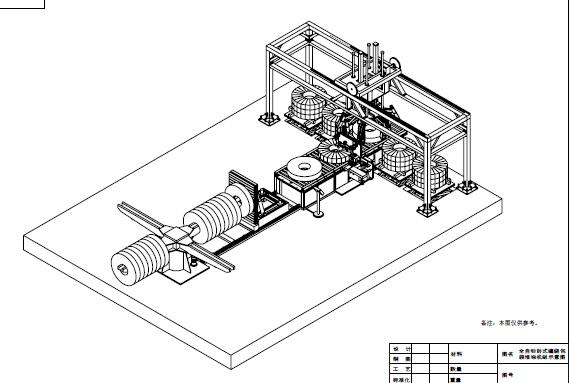

The first one is stretching the packaging equipment, and the second is the effect of the film.

Do you know how to stretch the packing properly? One important factor that can be applied is whether it is a product support failure. First of all, we all know that the compatibility between the film and the stretching packaging machine needs to be ensured, which is important. Mandatory load measurement is another area that needs to be tested. Or, the amount of strength/force used to combine the product together needs to be tested. (in LBS).

It is very important to monitor whether the recommended pretension is adhered to during the process.

If there is not enough capacity, there is a greater risk for pallet load. Seal failure and damage are things that need to be prevented. Packaging each load is a very important thing. Pre-determined containment standards need to be met.

You need to fix the load to the tray. Or the keys loaded to the pallet need to be created, which are the key elements of an effective stretch wrapper. Any long or drag film tail needs to be eliminated. Load keeping on the tray also needs to be ensured.

You can look at our recent web webinars and stretch your tray loads in the best possible way.

Wrinkles are affected by heat and humidity.

In the first 30 days of storage, the strength of corrugated paper has decreased, and in general, it will fall by 40%.